From Scan to Solution

Precision scanning and detailed 3D modeling transforms broken or obsolete parts into reliable solutions. Follow along as reverse-engineering, improvement, and manufacturing create custom components that stand the test of time.

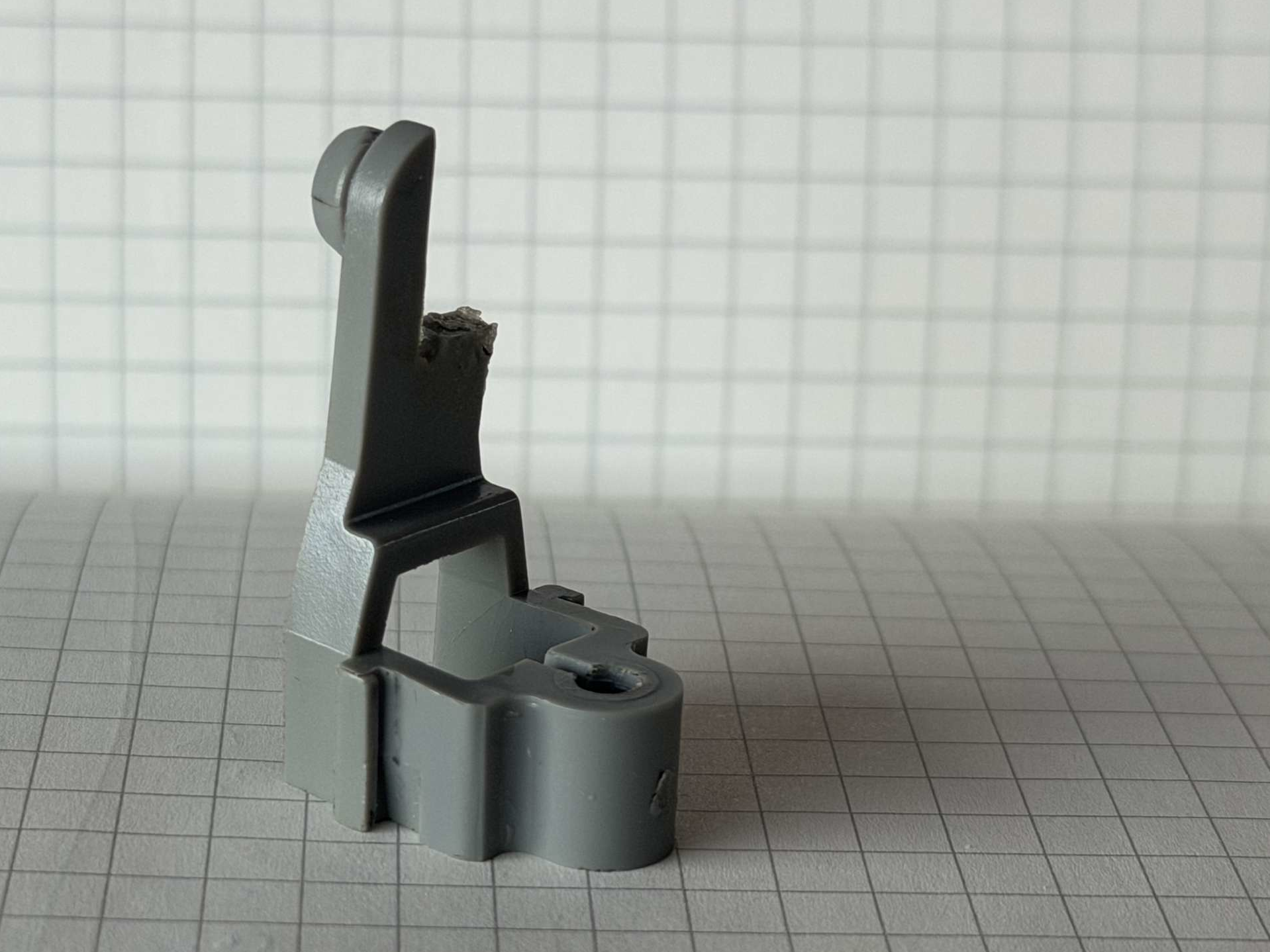

Project Assessment

Your project begins with the arrival of your damaged or obsolete part. The component is carefully examined to understand its function in the system and determine if reverse engineering is feasible. This initial assessment ensures the challenges are fully understood and sets expectations for a successful outcome.

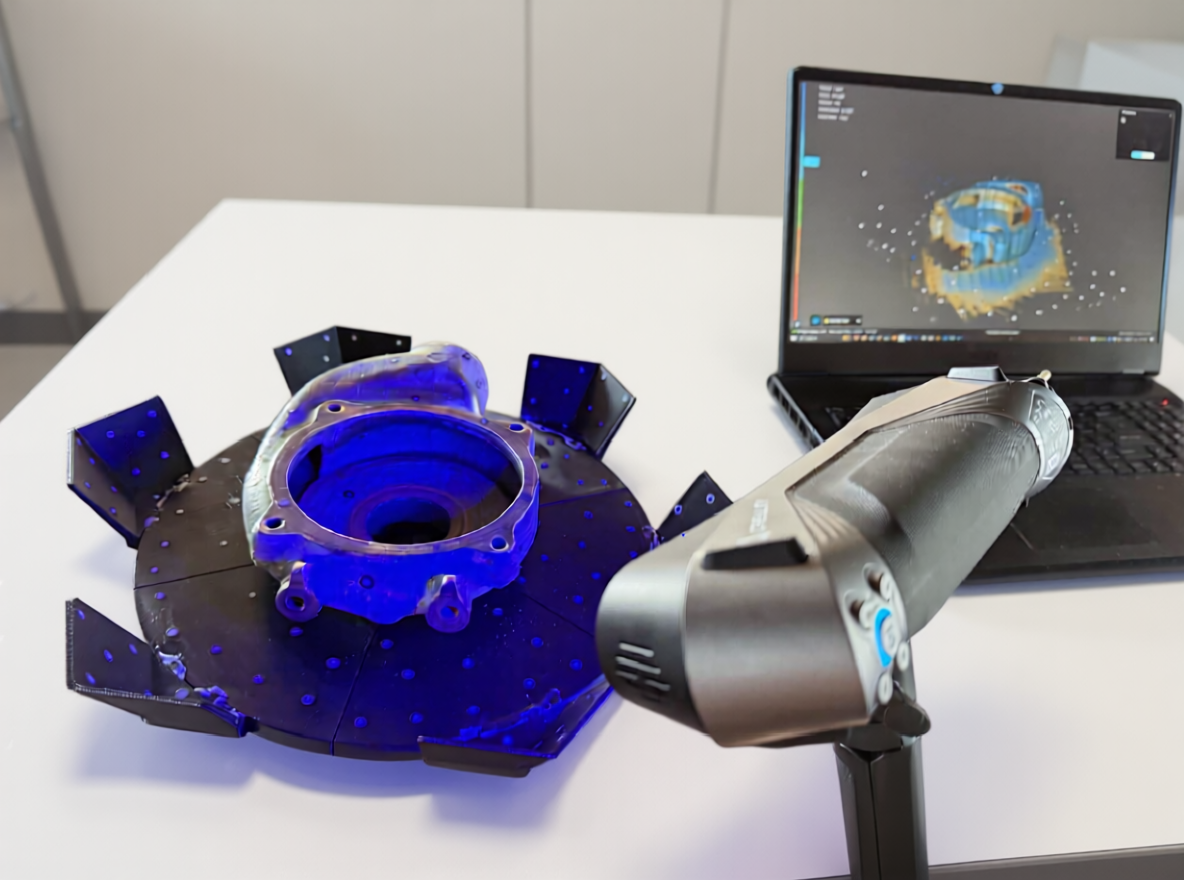

Digital Capture

State of the art 3D scanning equipment creates a detailed point cloud of your part. This digital representation captures every curve, feature, and dimension with high precision, forming the foundation for accurate modeling. The data serves as the digital blueprint for the entire reverse engineering process.

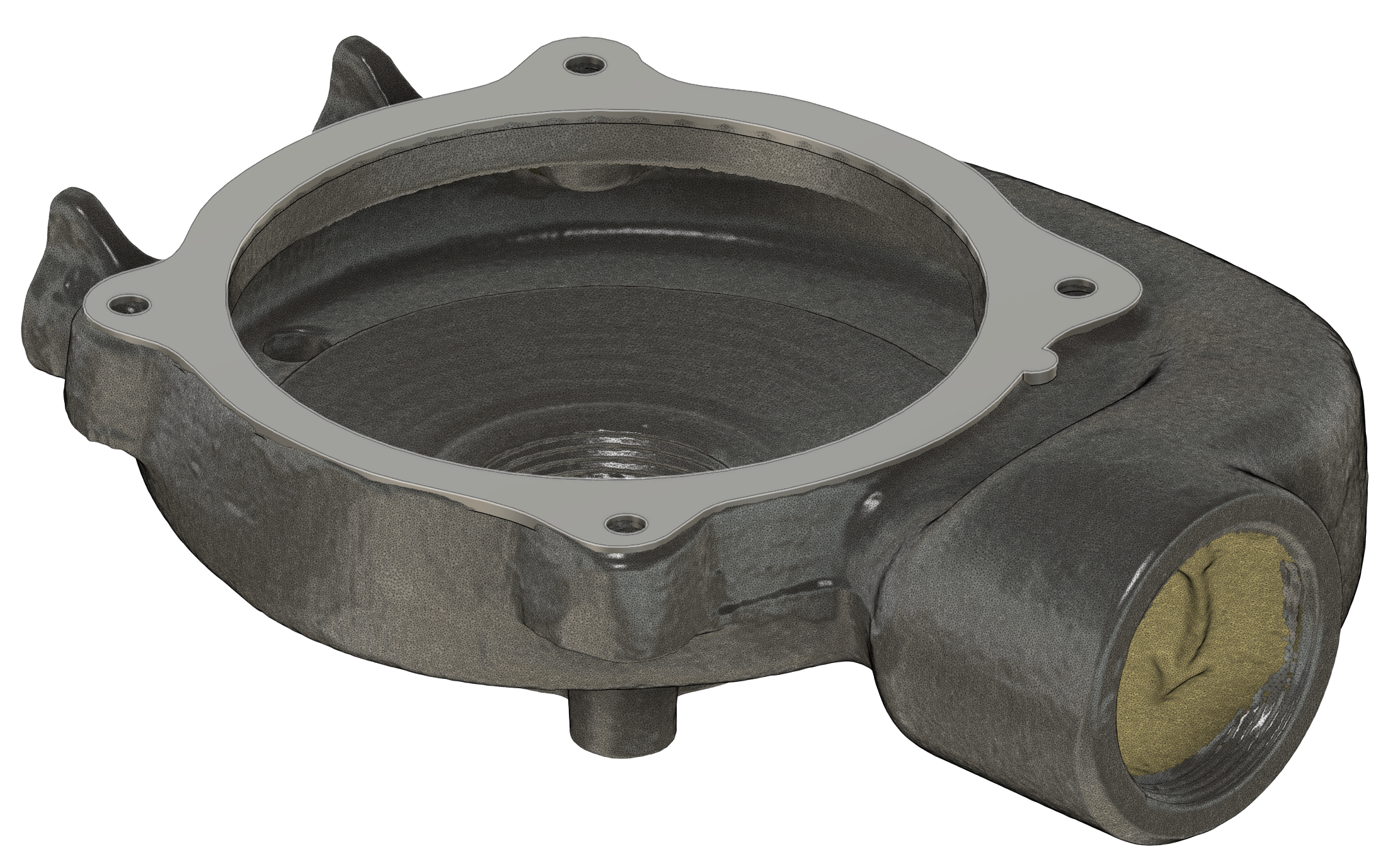

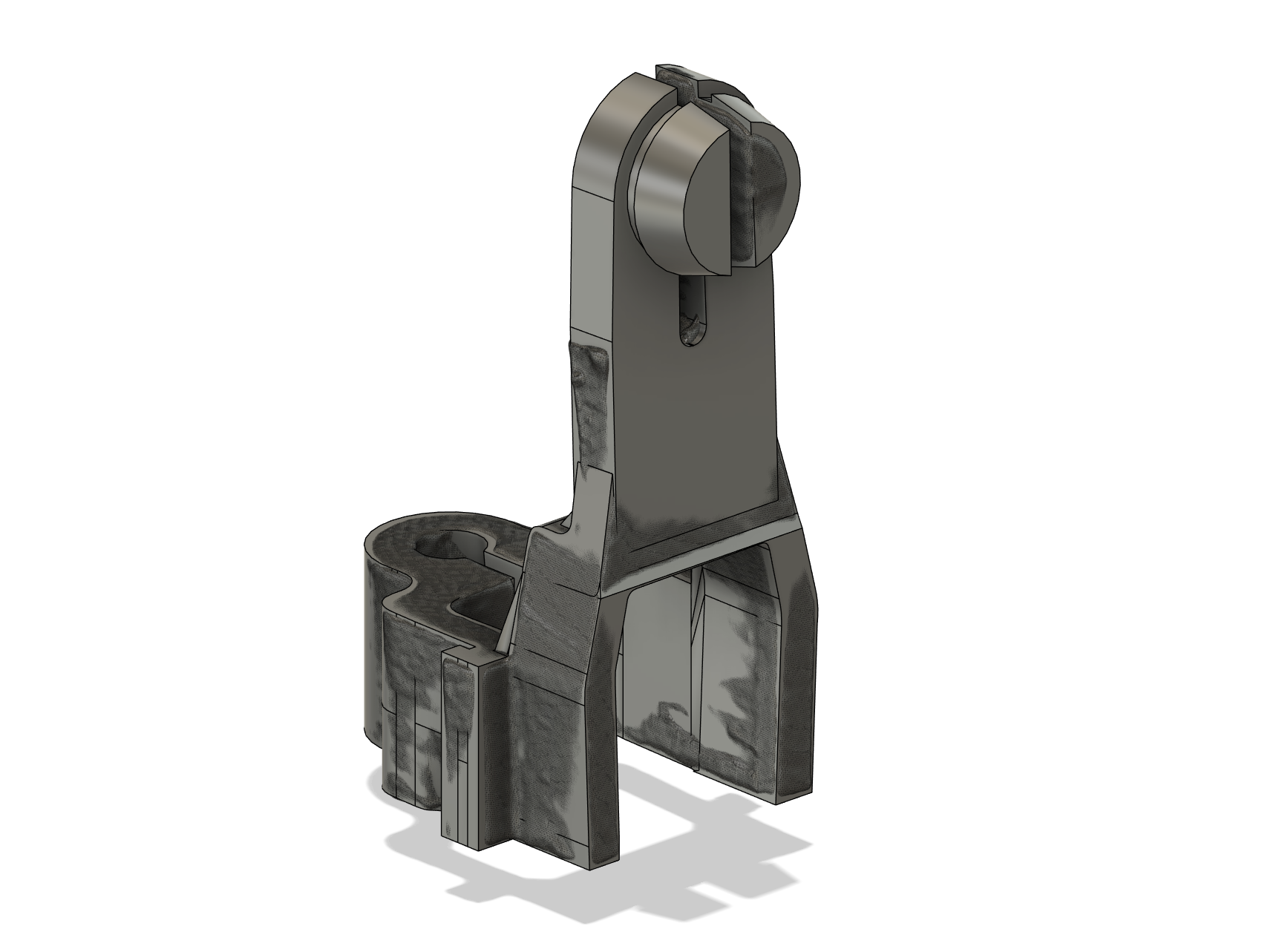

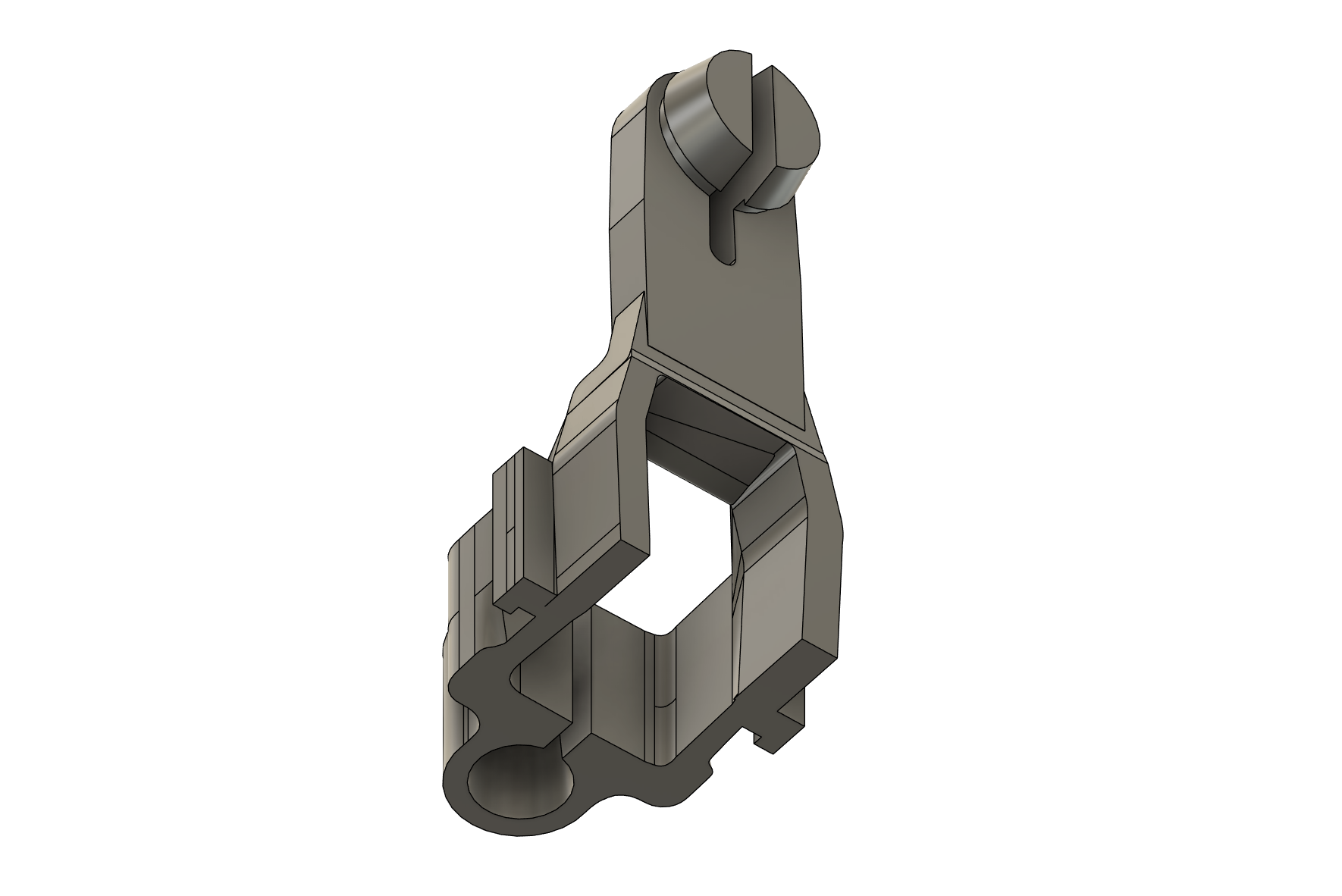

Precision Modeling

The scanned data is imported into CAD software where a detailed 3D model is built. Every feature, hole, and surface is recreated accurately, ensuring the virtual part matches the physical reality. This step provides a manipulable digital twin for optimization and manufacturing.

Accuracy Validation

The 3D model undergoes rigorous dimension verification against the original part. Precision measurement tools confirm critical tolerances and features are captured correctly. This quality control step reduces measurement errors and ensures the final product will function as intended in your application.

Design Optimization

This demonstrates going beyond replication. By analyzing the original design, weaknesses and areas for improvement are identified. Structural enhancements, material optimizations, and modern engineering principles are applied to create a part that's better than the original in strength, durability, and performance characteristics.

Material Selection

Material selection considers your part's application, environment, and stress factors. Multiple manufacturing methods are utilized based on requirements:

Additional Materials & Manufacturing Methods

When projects demand materials or tolerances beyond in-house capabilities, coordination with trusted third-party manufacturing services ensures proper execution with CNC machining, resin casting, and composite fabrication. Below is the extended list of available materials:

Completion & Handover

The final component receives meticulous analysis to optimize accuracy and compatibility. Should inaccuracies result in dimensional variances or compatibility issues, resolutions are pursued through design iterations. For complex parts requiring multiple iterations to achieve perfection, charges reflect the actual time invested.